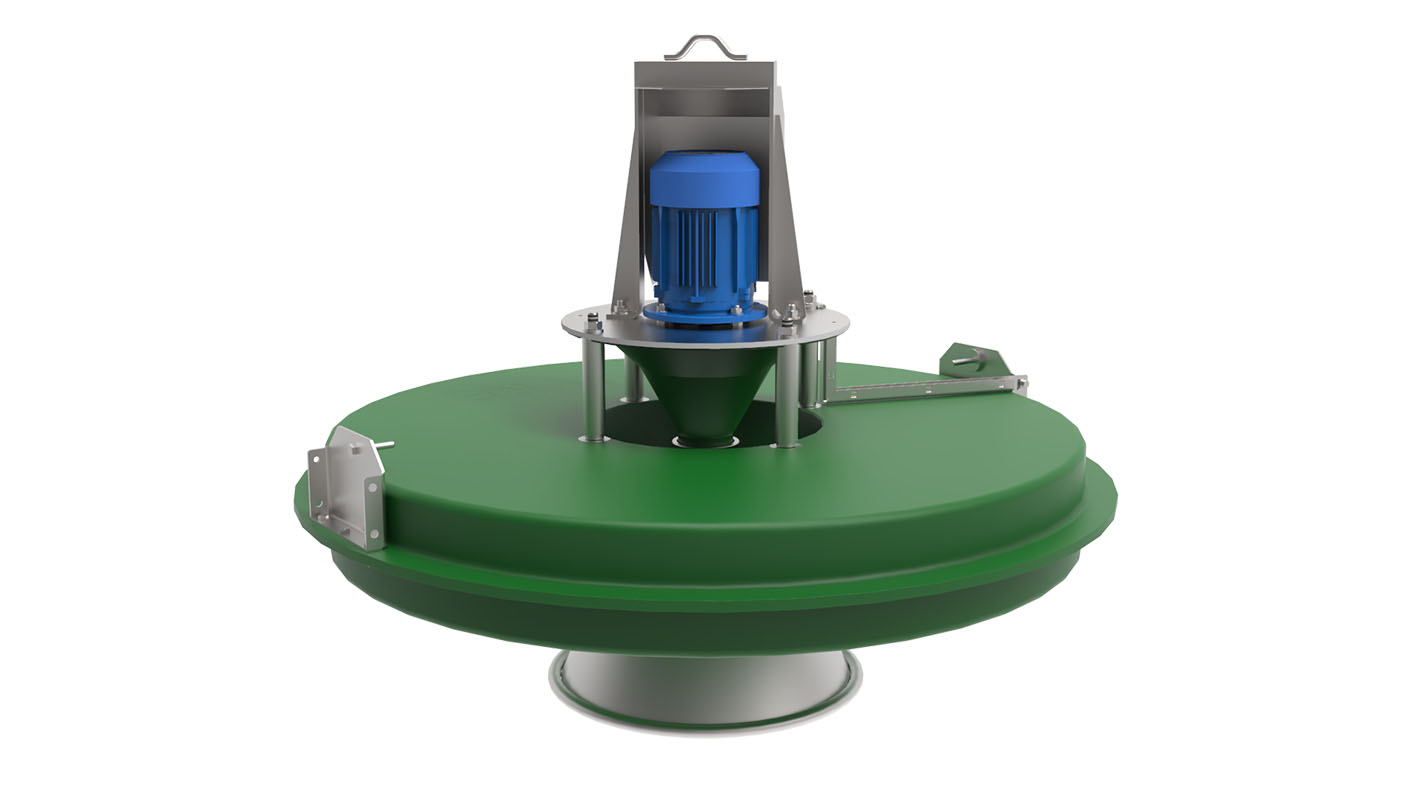

FLOPULSE is a fast floating aerator for wastewater treatment applications. This high-speed aerator enables an optimum oxygen transfer to improve the water quality of your lagoons, buffer tanks, leachate ponds, etc. This floating unit helps you to decrease the levels of DOB5 and DOC present in your wastewaters but also helps you to avoid any fermentation of the organic load and emergence of smelly odors.

WHAT IS IT FOR?

The surface aerator FLOPULSE enables the biodegradation of DOB5, DOC and TSS thanks to the oxygen supply it brings to wastewaters. This high-speed aerator transfers oxygen into the air by creating a spray of particles. Thus, the water is enriched in oxygen and mixed at the same time. FLOPULSE offers an optimum oxygen transfer that is very effective for wastewater treatment. This oxygen transfer also enables to control the development of smelly odours and algae proliferation.

is built with high qualitative materials to resist the most corrosive wastewaters.

An efficient machine

FLOPULSE’s oxygen supply enables the biodegradation of the organic loads, such as DOB5, DOC and TSS. It is mainly used to reach the legal discharge standards imposed by different countries and authorities.

To complete your product

For deeper basins, FLOPULSE can be combined with the hydro-ejector HYDROPULSE to ensure a homogenous oxygen transfer into the whole basin. HYDROPULSE is also benefit for its mixing capacities.

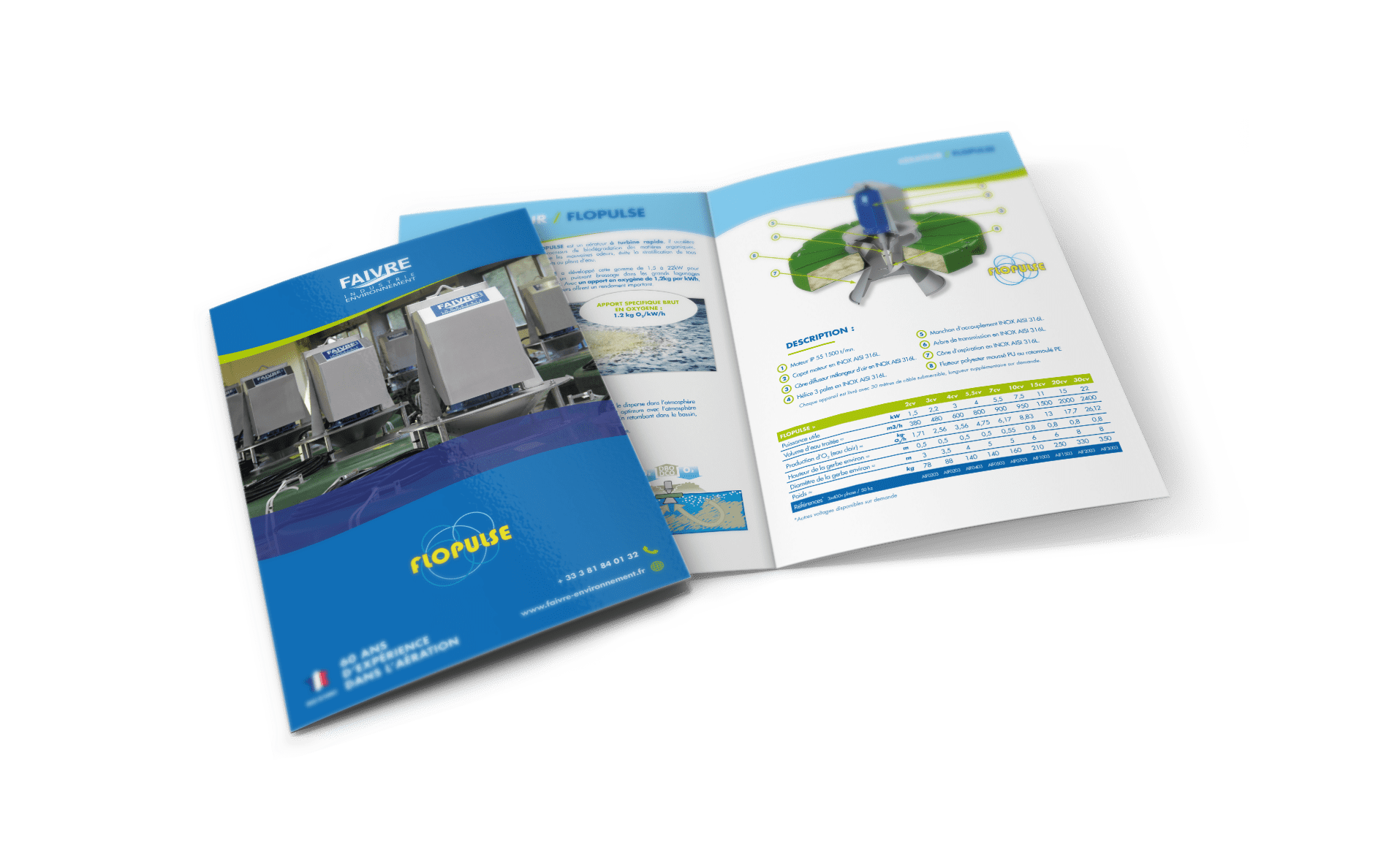

TECHNICAL CHARACTERISTICS

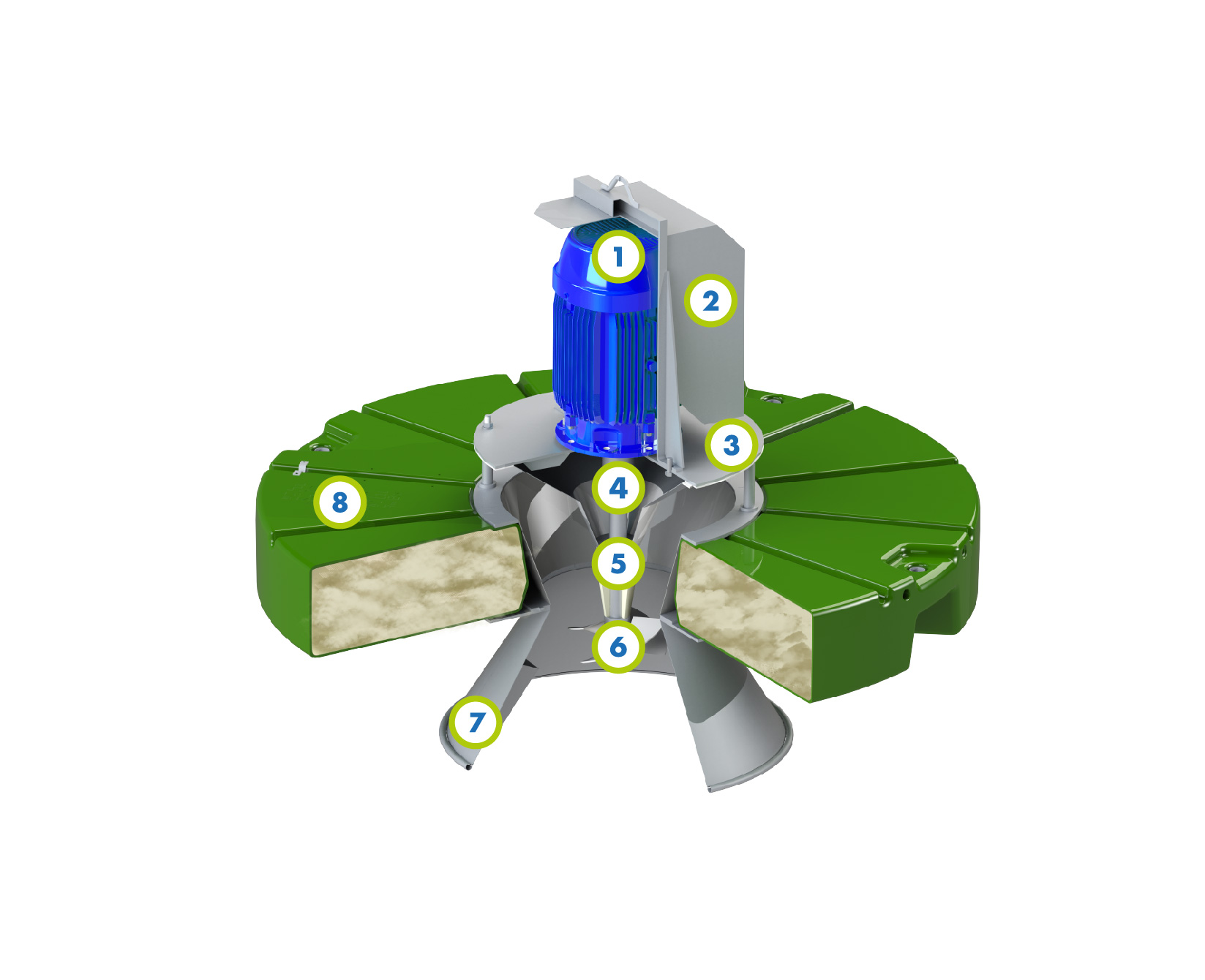

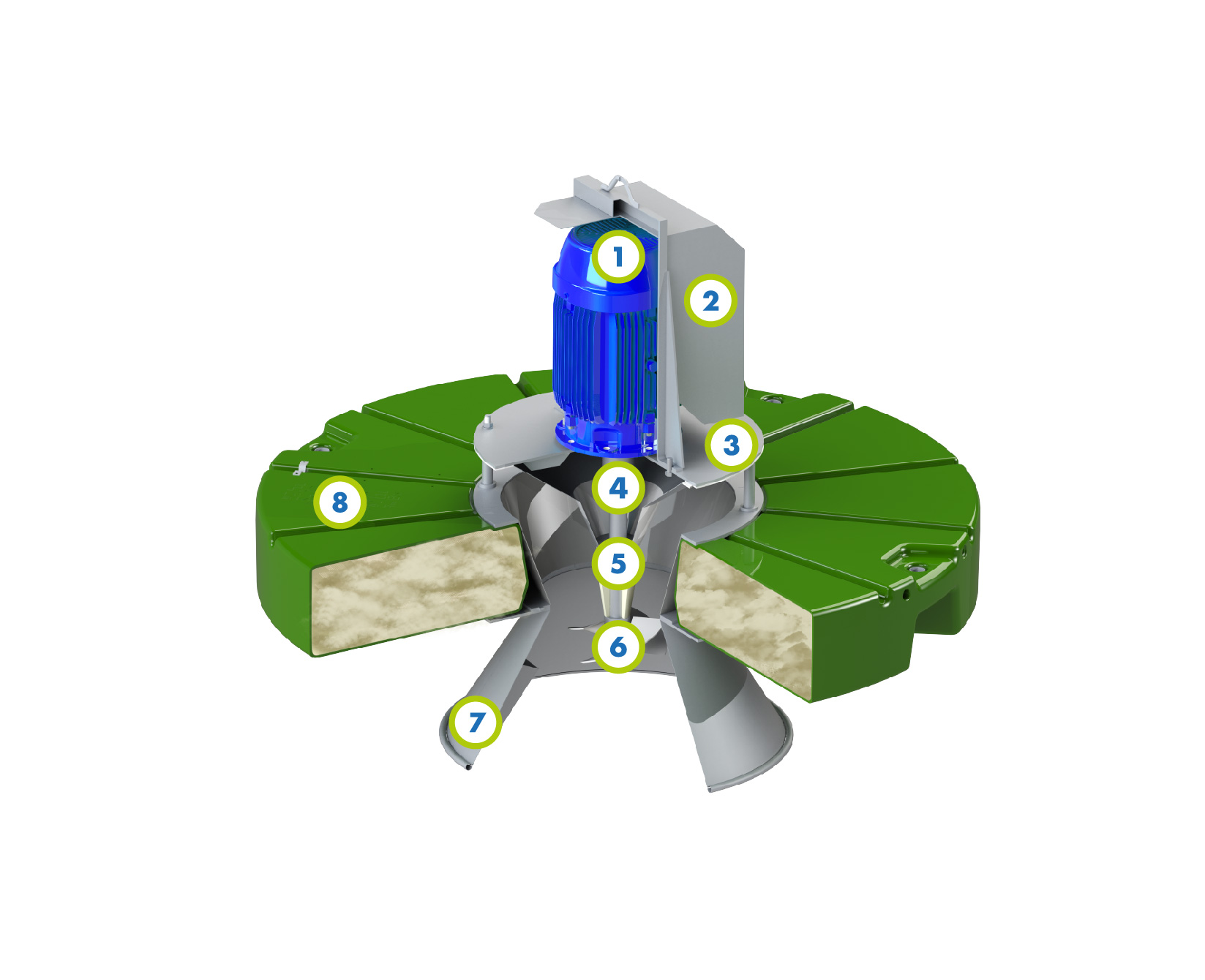

The fast floating aerator FLOPULSE is made with high qualitative materials and is available in 9 power supplies.

Engine IP 55 1500 t/mn

Engine IP 55 1500 t/mn

Engine cover in stainless steel AISI 316L

Engine cover in stainless steel AISI 316L

Air mixer diffuser cone in stainless steel AISI 316L

Air mixer diffuser cone in stainless steel AISI 316L

Stainless steel coupling sleeve AISI 316L

Stainless steel coupling sleeve AISI 316L

Transmission shaft in stainless steel AISI 316L

Transmission shaft in stainless steel AISI 316L

3 blade propeller in stainless steel AISI 316L

3 blade propeller in stainless steel AISI 316L

Suction cone in stainless steel AISI 316L

Suction cone in stainless steel AISI 316L

PU foamed polyester float or rotation-moulded PE

PU foamed polyester float or rotation-moulded PE

Performances

are French-made