We've received the "Made in France" Certification

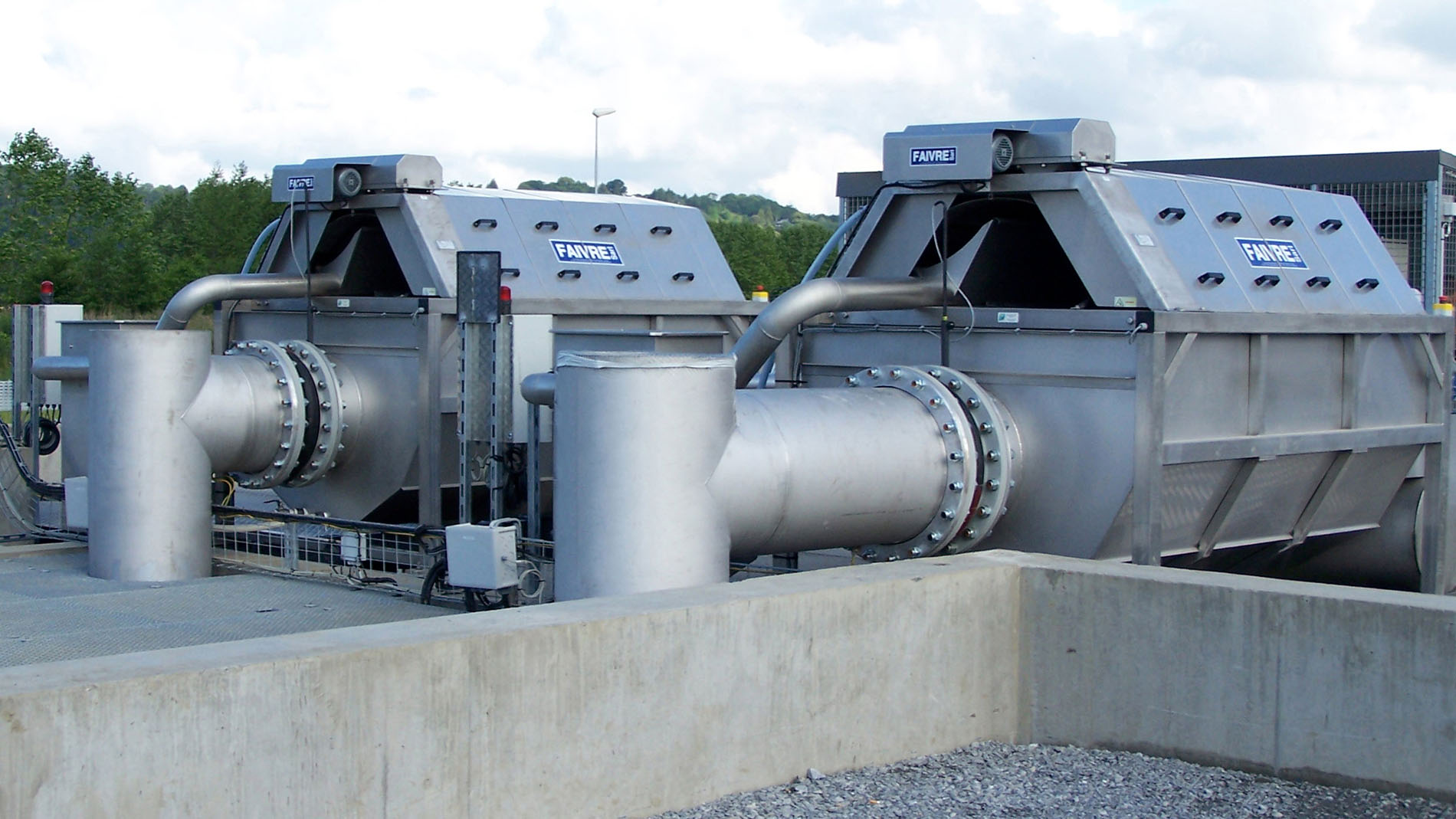

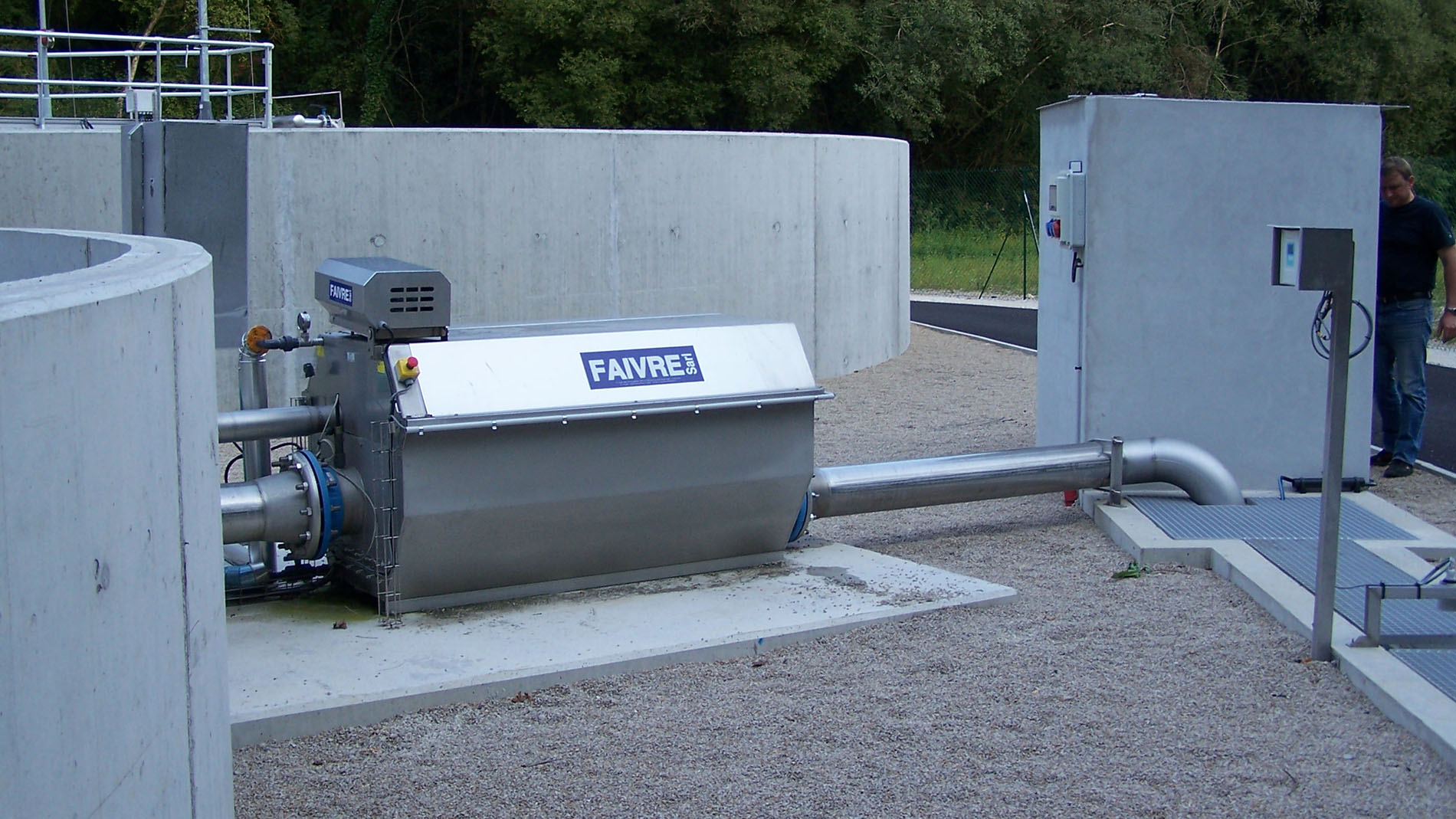

ROTOCLEAN is a range of rotary drum filters designed to reduce pollutants from municipal and industrial wastewater treatment plants. Our drum filters are designed to be setting up in the tertiary treatment of the wastewater cleaning process. The drum filter technology helps in the liquid-solid separation in order to meet local and federal effluent regulations.

WHAT IS IT FOR?

The drum filter is a mechanical and self-cleaning machine. It has low energy consumption and its fully automatic working system enables a filtration process without interruption. This technology has a capacity to filter high flows of liquids.

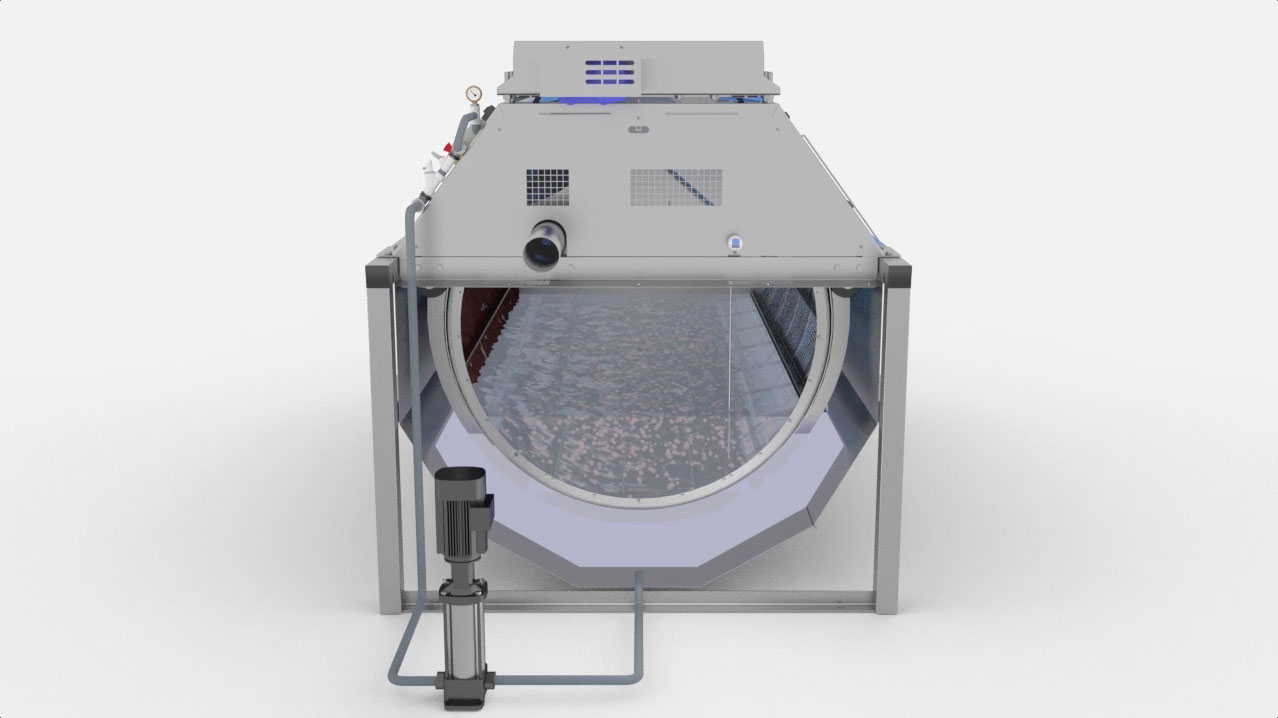

The wastewaters flows by gravity from the inside of the drum filter to the outside. The drum of the filter is circled with micro filter mesh panels which enable to remove the suspended solids bigger than the mesh. The suspended solids are then discharged by a sludge channel. The filter panels are cleaned by a rinsing pump delivered with the drum filter. The water used by the pump is taken from the filtered water, to avoid pollution of clear water.

Easy to use

A rinsing ramp present on the filter cleans the filter plates all along the filtration process. The sludge is evacuated by a specific chute. The slow rotation speed of the drum filter enables an optimal filtration output. The concentration of Suspended Solids is highly decreased thanks to the thickness of filtration.

Many advantages

ROTOCLEAN is a self-cleaning drum filter which resists to corrosion. With a maintenance reduced, our range of drum filters is robust and has a low economic cost.

TECHNICAL CHARACTERISTICS

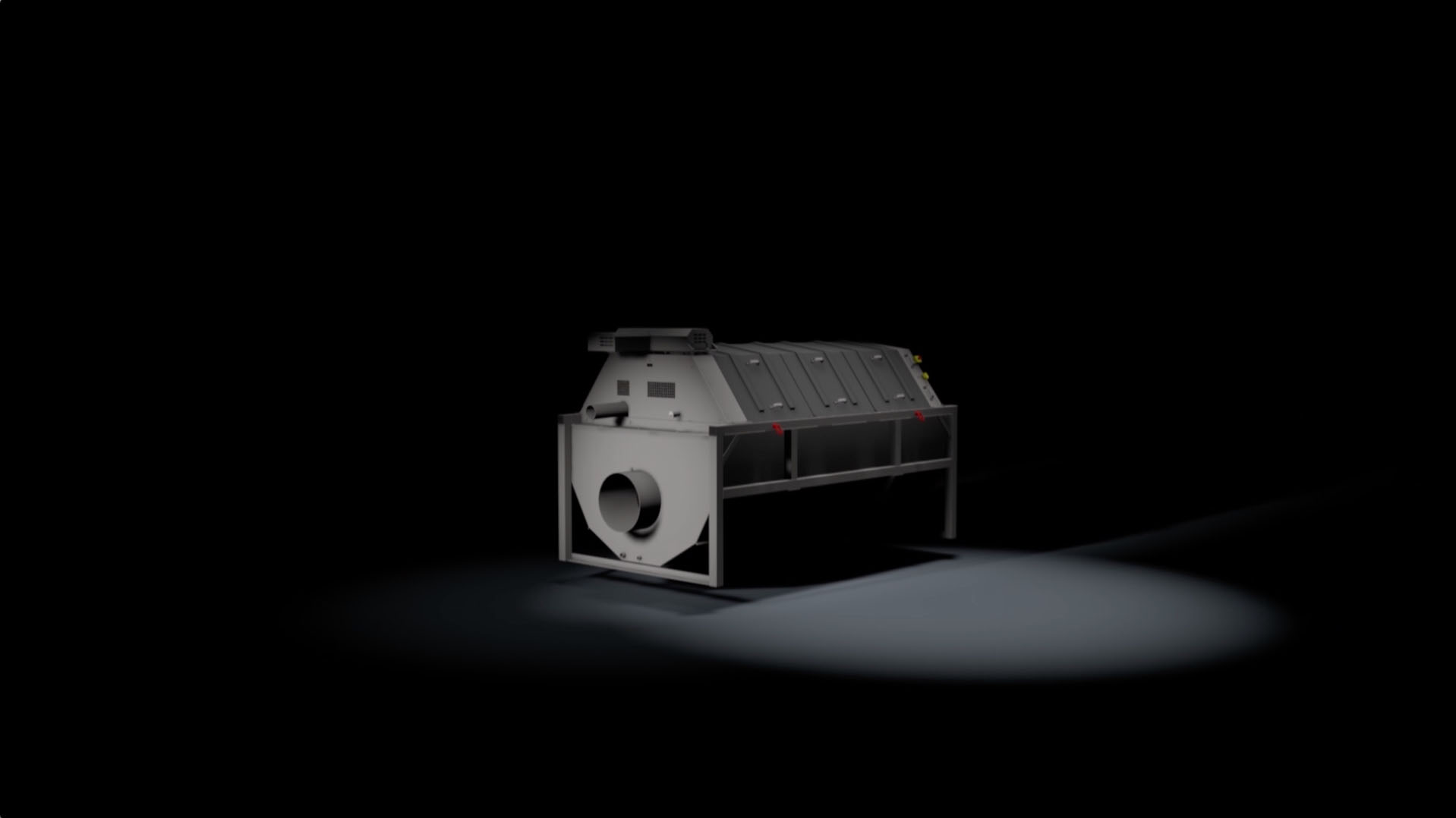

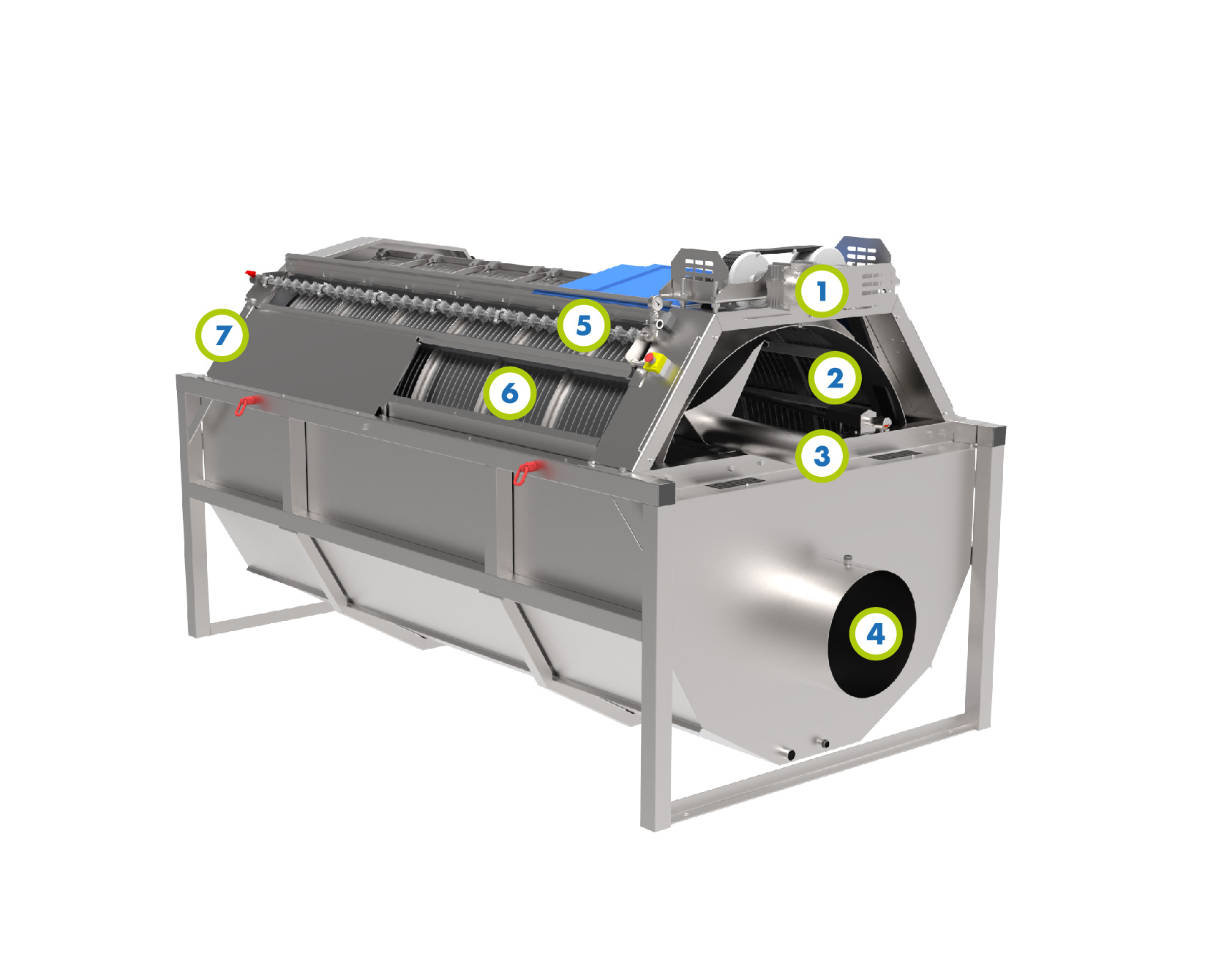

Every model of ROTOCLEAN is composed with the same elements. Designed with high qualitative materials, these drum filters resist to the most corrosive effluents.

Drum motor

Drum motor

Belt (BDS System)

Belt (BDS System)

Sludge chute

Sludge chute

Inlet water (waste water)

Inlet water (waste water)

Nozzles

Nozzles

Filter plates

Filter plates

Outlet water (clean water)

Outlet water (clean water)